Automotive Parts Inspection Equipment Solution

Leader in Pressure Component Measurement and Control Technology

As a long-term supplier of testing equipment for one of China's top 5 national-level automotive laboratories, FST has many years of experience in R&D and manufacturing of automotive component testing equipment. At the same time, FST has a long-term cooperation with Wuhan University of Technology, providing strong support in technology, qualifications, and markets, to ensure the sustainable and stable development of testing business.

Pressure-bearing parts that can be tested include the braking system, power steering system, fuel system, air conditioning system, cooling system, and turbocharging system of automobiles. The testing media include oil, gas, water, and automobile coolant. The testing types include dynamic and static, and the testing pressure ranges from vacuum to ultra-high pressure.

The applicable standards include the standards of major car manufacturers such as Volkswagen, General Motors, Ford, Peugeot, First Automotive Works, Dongfeng, SAIC, Changan, Geely, and Great Wall, as well as international standards such as ISO, SAE J, FMVSS, and domestic standards such as GB and QB.

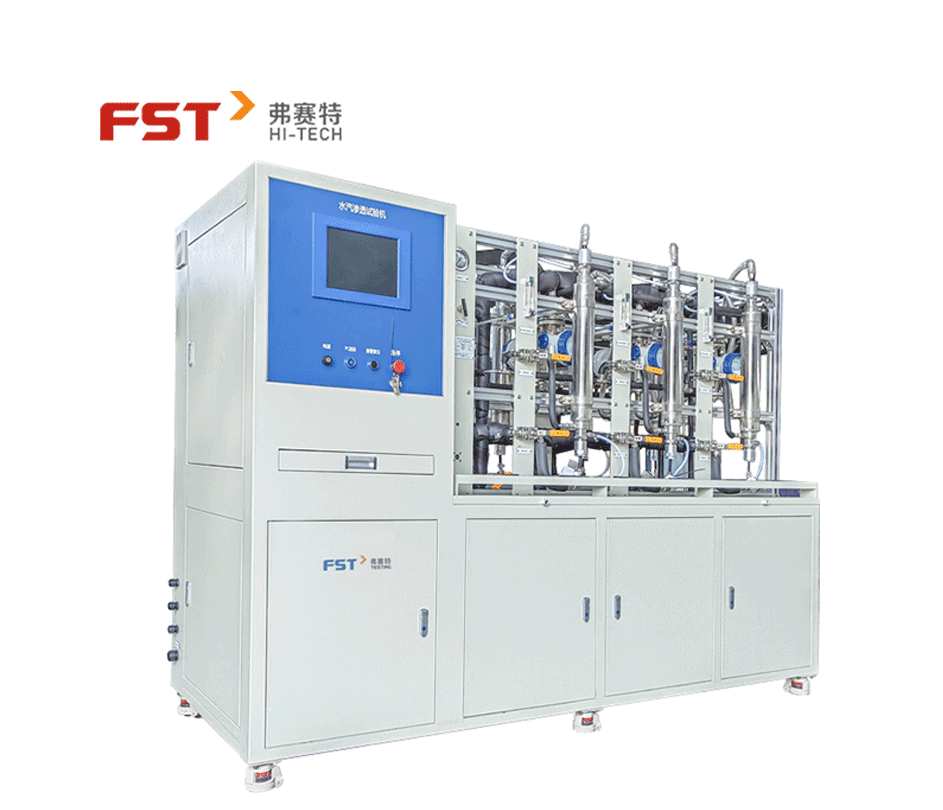

Water-based PVT Testing Machine

This is a comprehensive testing machine specifically designed for testing specimens that use automotive coolant and have small pulse pressures, high pulse frequencies, and large expansibility, using a dynamic composite loading of internal pressure (P), external vibration (V), and (internal and external) temperature (T) to test the reliability of the specimens. It can also perform tests for flow rate (medium) and humidity (environment).

It is a servo-hydraulic closed-loop control system that is specially developed for testing specimens such as liquid-cooled plates, cooling hoses and joints, radiators, and heating cores of automotive cooling systems. The pressure waveform and test temperature are adjustable and controllable.

Applicable objects: liquid-cooled plates, cooling hoses and joints, radiators, heating cores, etc. in automotive cooling systems.

Applicable standards: GMW 14785, GMW 14329, GMW 18152, TL 52361, SAE J1610, GB 18948, QC/T 468, etc.

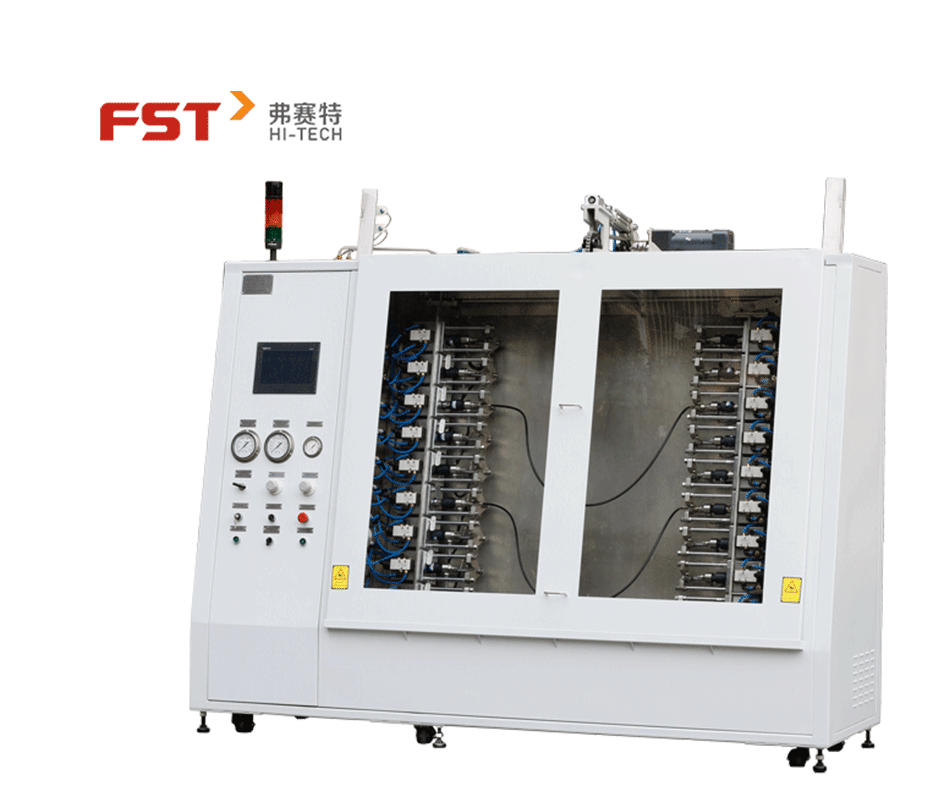

This machine simulates the actual working conditions of a vehicle by using dynamic composite loading of internal pressure (P), external vibration (V), and internal/external temperature (T) to test the reliability of test pieces. It also has a humidity (environmental) testing function. It uses servo control technology to set the pulse pressure waveform, pulse frequency, pulse count, medium temperature, and ambient temperature within a controllable range.

The oil pulse test machine is suitable for testing air conditioning pipes, condensers, evaporators, brake hoses, power steering hoses, fuel pipes, and other components. The gas pulse test machine is suitable for testing fuel hoses, turbocharger hoses, intercoolers, and other components.

Applicable standards:GMW16153, GMW 14192, GMW 14319, GMW3056, TL 82253, TL 82316, TL 82415, SAE J1401, SAE J2044, FMVSS106, ISO 11425, GB/T 16897, QC/T 664, etc.

The permeation testing machine is used to test whether the permeability of automotive cooling/fuel system hoses and quick-connect fittings meets standard requirements after long-term stable cooling/fuel circulation.

Water vapor permeation testing machines are used for automotive cooling system hoses and fittings. Standard: GMW 18152.

Fuel permeation testing machines are used for automotive fuel system hoses and fittings. Standard: SAE J1737.

Widely used for pressure resistance and burst tests on various metal pipes, nylon pipes, rubber pipes, and small pressure components. It is used to test the maximum pressure that automotive fittings can withstand under certain conditions and to determine whether the quality of the test piece meets the relevant standards.

Application: Basically applicable to all small pressure components of automobiles.

The volume expansion test machine is used to test the volume expansion of pipes under internal static hydraulic pressure. When transferring liquids of specified volume through hoses, it is required that the hoses should not undergo significant volume changes or only have minimal volume changes under transfer pressure.

The proportional volume expansion test machine is suitable for testing various brake hoses and power steering hoses of automobiles.

Standards: FMVSS106, GB/T 16897, GB/T 20461.

The small volume expansion test machine is mainly used to test high-performance hydraulic brake hoses of automobiles. Standard: GMW3056.

The online leackage test machine is suitable for online pressure testing and inspection of automotive pipeline components in the production line and workshop to determine whether the product meets the factory standards.

The online water pressure test machine is suitable for testing automotive hydraulic brake hoses.

Applicable standards: GB/T 16897, SAE J1401.

The online airtightness test machine is suitable for automotive air brake and vacuum brake components.

Applicable standards: GB/T 16897, TL876.

Shenzhen Fluid Science&Technology Corp., Ltd.

Headquarter:

No. 513A, East Block, Coast Building, Nanshan District, Shenzhen, Guangdong, China

Tel:

© Shenzhen Fluid Science&Technology Corp., Ltd. ALL RIGHTS RESERVED | 粤ICP备10233873号 | Legal Declaration