Other Specialized Equipment

FST has extended a series of high-value products in projects such as choke manifold and wellhead control systems.

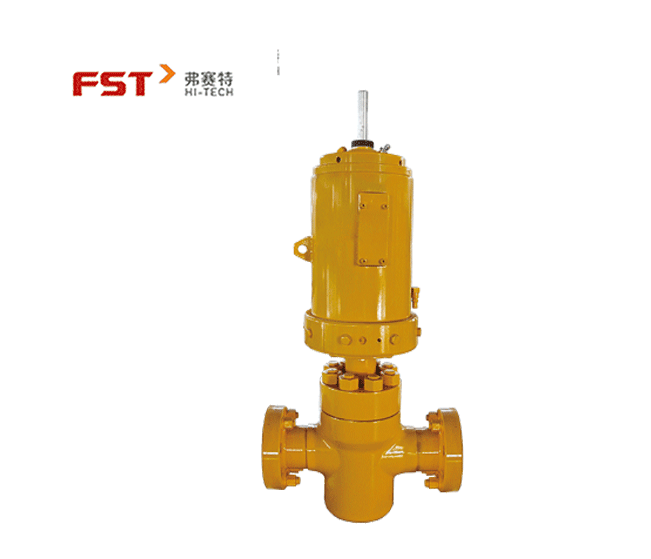

The Surface Safety Valve, together with the Wellhead Control Panel, forms the Wellhead Safety Control System.

Our Surface Safety Valve is a type of linear motion valve driven and controlled by pneumatic or hydraulic, and relied on spring reset. It is applied in oil and natural gas well fields to provide safety protection in critical situations such as oil and gas leakage or fire. It can directly and quickly shut off the wellhead.

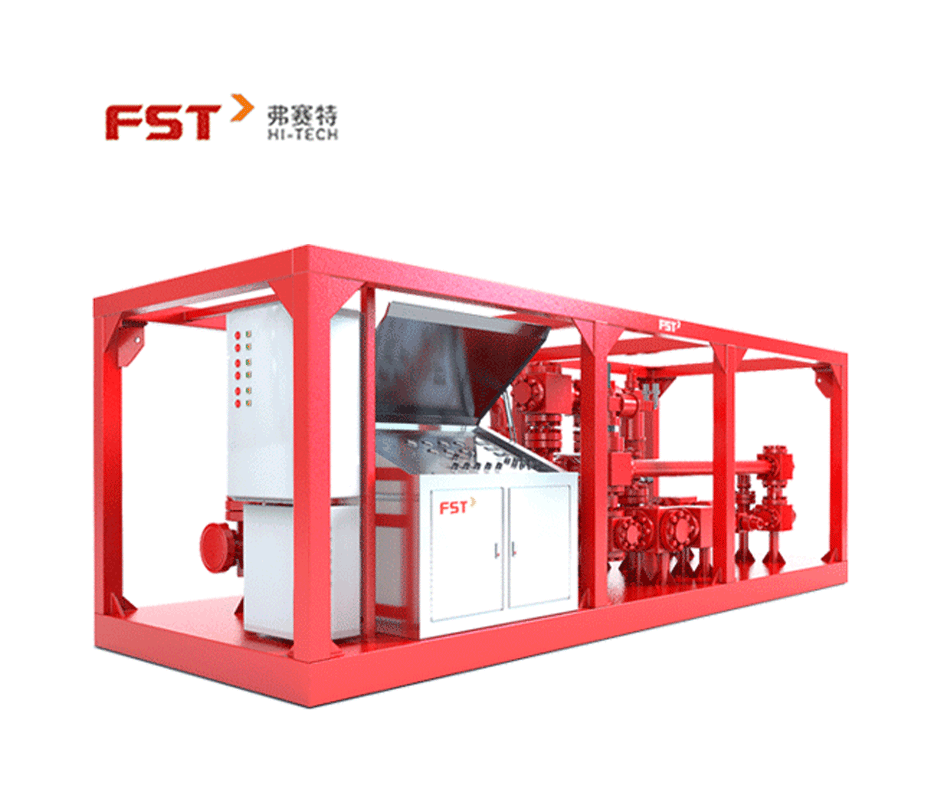

Managed Pressure Drilling System

The MPD system mainly consists of a choke manifold control system, backpressure compensation system, remote monitoring system, and software system. The system integrates pressure monitoring and micro-flow monitoring functions. Through self-developed automatic control software, it can accurately control the downhole pressure, achieving managed pressure drilling.

The MPD system treats the wellbore as a closed pressure system and sets the control objective for the annular pressure at the bottom of the well according to the upper and lower limits of the safe pressure interval. By using drilling fluid density smaller than the formation pore pressure and applying automatic throttling backpressure control technology, the system manages the pressure throughout the wellbore in a closed loop, counteracting the pressure fluctuations generated by drilling, stopping pumping, adding or removing drill pipes, and other drilling operations, thereby effectively addressing complex drilling problems such as density window, pressure-sensitive formation leak-off, same-layer formation drilling, and borehole collapse.

Application objects/scenarios: oil and gas drilling operations.

The control system that manages the manifold valves at the wellhead uses pneumatic-hydraulic/electro-hydraulic logic. It can meet the working requirements of various sizes of manifolds, maintain stable wellhead pressure, ensure the safety of wellhead production, protect wellhead equipment and pipelines, protect oil and gas resources and the environment, prevent pollution, and is easy to operate with stable performance, saving labor and reducing the labor intensity of outdoor operations.

It can remotely control the opening and closing of the hydraulic choke valve, and display the standpipe pressure, casing pressure, and valve position of the hydraulic choke valve on the control box to maintain the bottom hole pressure. It is necessary equipment for successfully controlling well kicks and blowouts, and implementing oil and gas well pressure control technology.

Application object/scenatios: control of various valves on the choke manifold.

Oil Casing Gas-tight Joint Detection Device

This refers to a device used to test the gas-tightness of the threaded connection of an oil casing. After the connection is made, a high-pressure booster is used to pressurize a mixture of high-purity helium and hydrogen to the testing pressure. The upper and lower parts of the thread of the isolation tool form a closed space inside the oil casing, and the gas-tightness of the oil casing thread is tested using the characteristics of the small molecular weight and easy leakage of helium.

Application object/scenarios: gas-tight joint detection of oil casings.

Shenzhen Fluid Science&Technology Corp., Ltd.

Headquarter:

No. 513A, East Block, Coast Building, Nanshan District, Shenzhen, Guangdong, China

Tel:

© Shenzhen Fluid Science&Technology Corp., Ltd. ALL RIGHTS RESERVED | 粤ICP备10233873号 | Legal Declaration