Pressure Testing Equipment

FST has led the design, construction, and overall solutions for multiple national-level high-temperature and high-pressure laboratories, representing the technological high ground for domestic high-temperature and high-pressure laboratory construction.

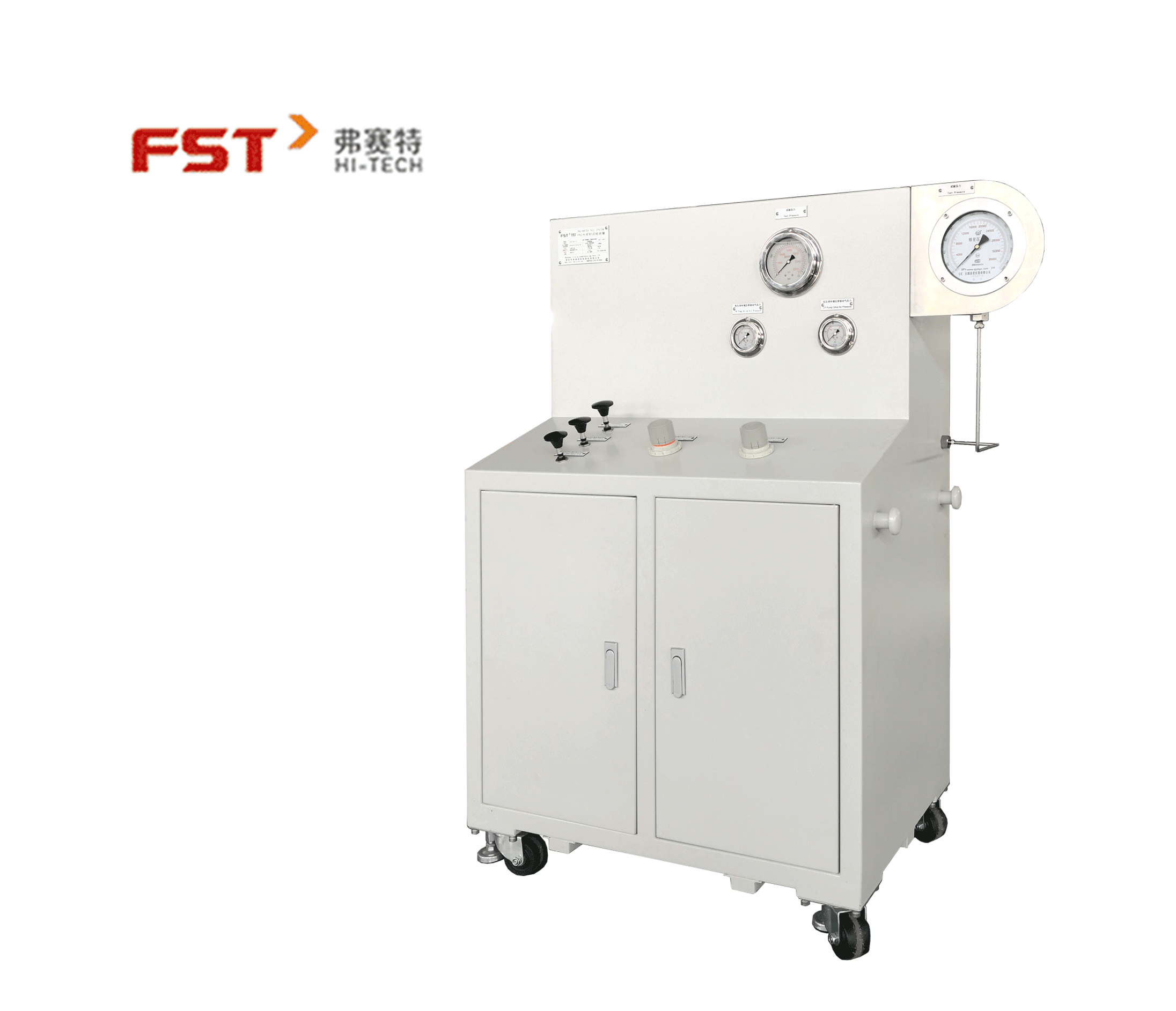

The gas tightness test bench uses high-pressure nitrogen to perform sealing tests on specimens, in order to meet the requirements of manufacturers and testing agencies for sealing tests on valves, wellhead Christmas trees, blowout preventers, and manifold.

For the gas tightness test of valves and wellhead Christmas trees, a multi-stage pneumatic booster pump is used for pressurization. The test meets the requirements of standard API Spec 6A and the specifications of PSL1-PSL4.

For the gas tightness test of blowout preventers and manifold, a hydraulic-driven booster pump is used, which has high efficiency and large displacement. The test meets the requirements of standard API 16A.

The sealing performance of the test piece is tested with high-pressure purified water to meet the requirements of manufacturers and testing organizations for water pressure testing of valves, wellhead Christmas trees, BOP, and manifold.

For the water pressure testing of valves and wellhead Christmas trees, a multi-stage pneumatic booster pump is used for pressurization. It complies with the American API 6A testing standard and the specifications of PSL1-PSL4.

For the water pressure testing of BOP and manifold, a hyraudlic-driven booster pump is used, which has high efficiency and large displacement. The test meets the requirements of standard API 16A.

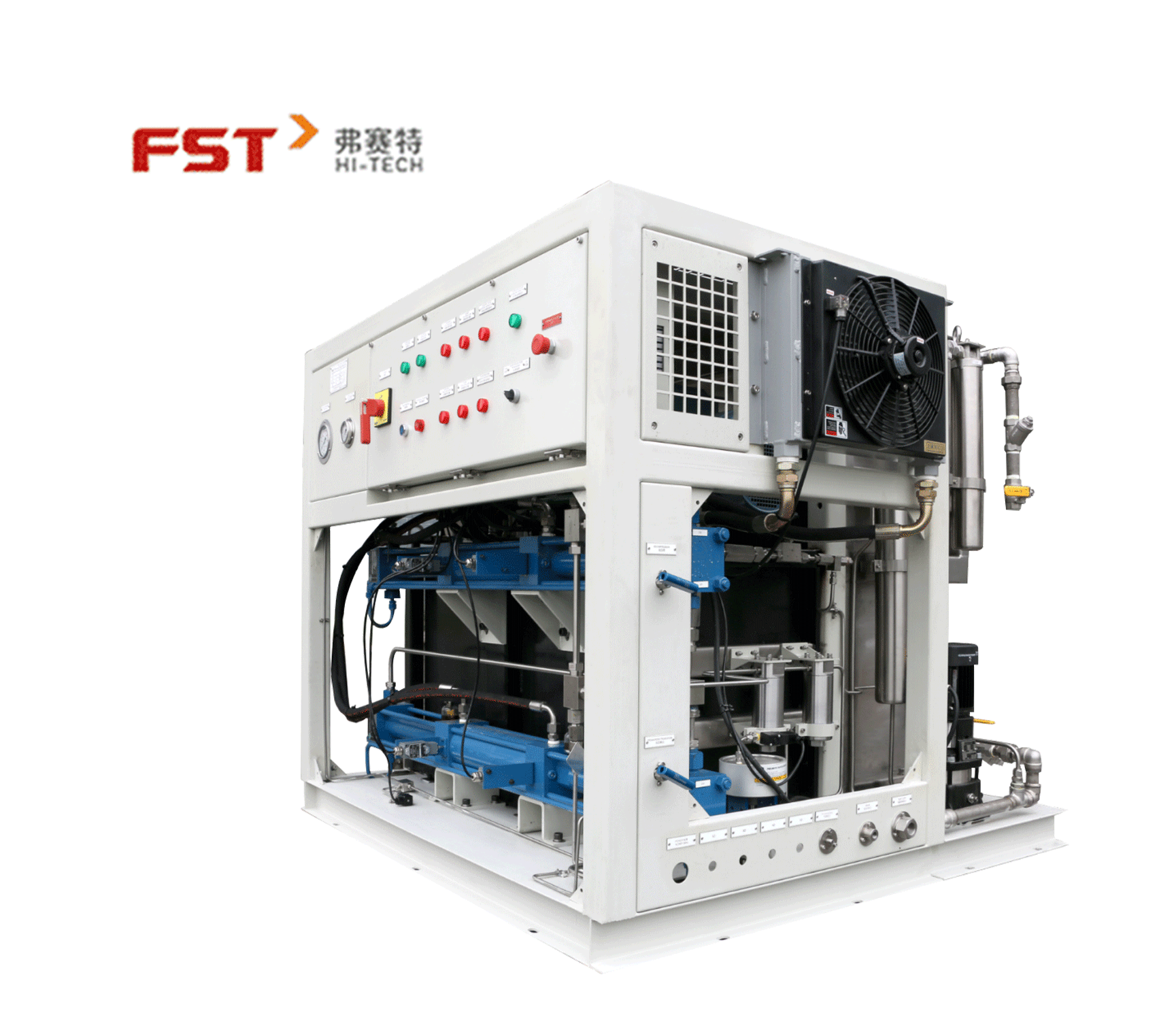

According to the different needs of customers, we have selections of pressure sources with different pressure levels and automation levels, which are widely used in various mobile pressure testing vehicles and containerized portable pressure testing equipment.

Application objects/scenarios: Various mobile pressure testing vehicles and containerized pressure testing equipment.

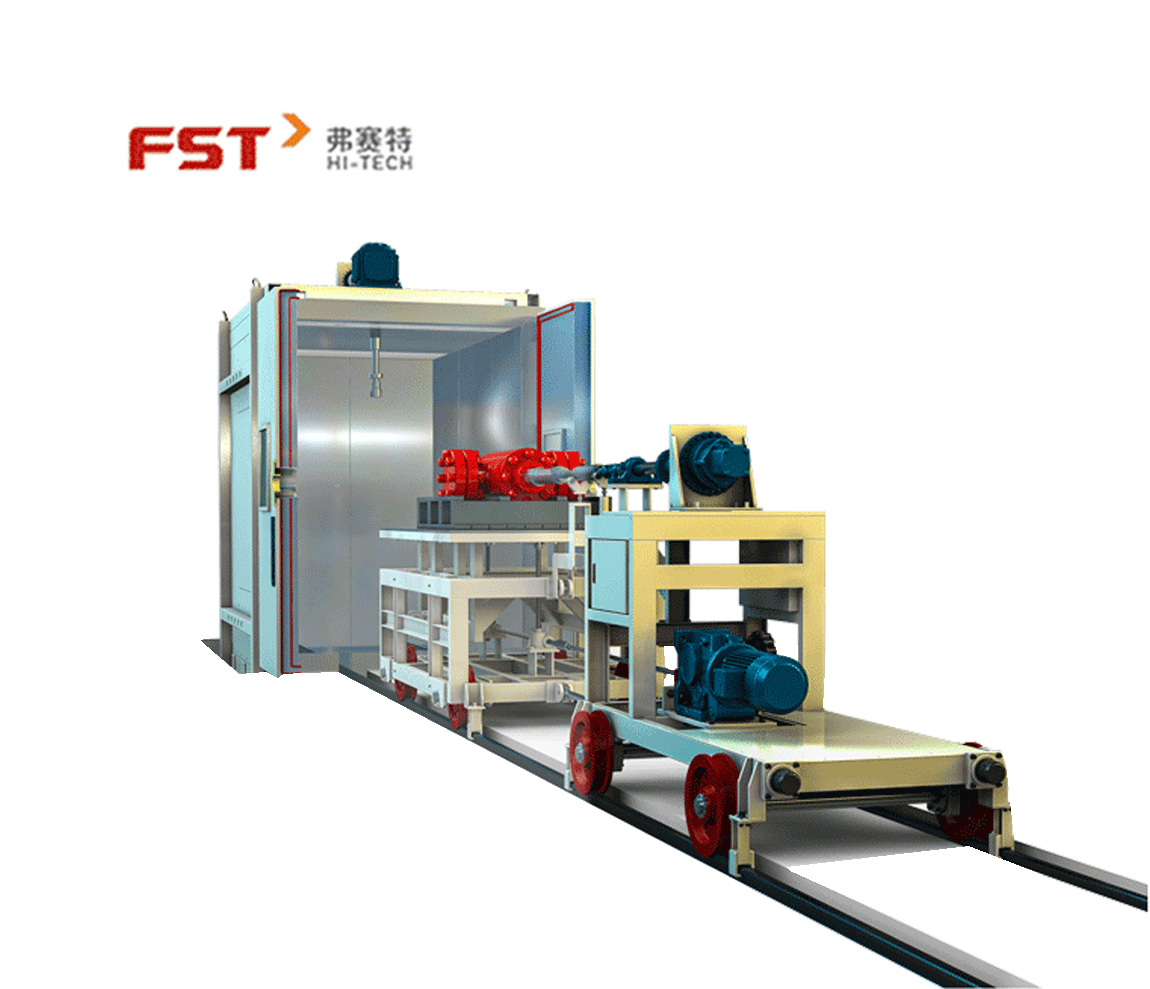

The PR2 system consists of a high and low temperature environmental chamber, valve driving device (torque testing tool), water/gas pressurizing equipment, measuring and control system, and monitoring system. It can automatically conduct test for the pressure, temperature, and torque combined cycle tests specified by the PR2 standard. It meets the requirements of standards such as API 6A, ISO 10423, GB 10592.

Application objects/scenarios: The strength and sealing test of ram BOP, annular BOP, valve, hanger, Christmas tree and other wellhead products, the dynamic test of valve opening and closing at maximum/minimum temperatures, valve pressure/temperature cycling tests, torque tests, etc.

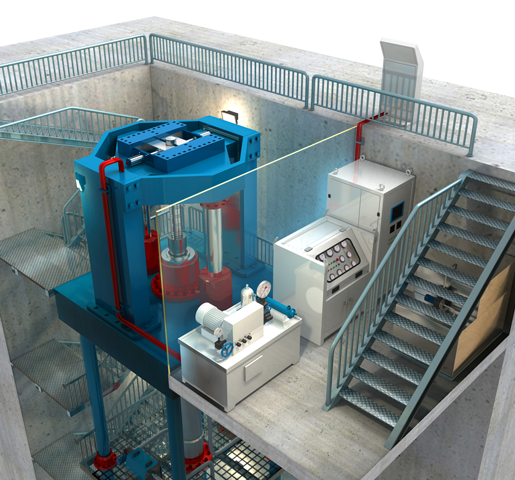

Wellhead Equipment and Blowout Preventer Test System

The testing system for wellhead equipment and blowout preventer consists of the following components:

The blowout preventer life testing machine is used in conjunction with other systems to complete fatigue test, constant well pressure test, constant hydraulic closing test, pressure-bearing and drilling life test, and hanging test. The locking device test, hydraulic control oil circuit cylinder strength test, core disassembly and assembly test, and shear gate test can also be performed on this device.

The blowout preventer pressure testing device opens or closes the device by switching different output circuits and has multiple circuits.

The non-metallic seal design temperature verification device performs high and low pressure testing on each temperature level of the blowout preventer.

The data measurement and control and video monitoring system monitor and control the entire testing process and achieve high automation control.

Application objects/scenarios: This system is used for testing the life, pressure, high and low temperature, sealing, and other properties of ordinary blowout preventers and rotating blowout preventers.

High-Temperature High-Pressure Testing System for Downhole Tools

The high-temperature high-pressure testing system for downhole tools mainly consists of a high-pressure/ultra-high-pressure testing well for downhole tools, an intelligent high-pressure/ultra-high-pressure oil, gas, and water boosting system, a force loading testing device, a circulation heating and insulation device, and a remote central measurement and control system.

Application objects/scenarios:

It is mainly used to simulate the high-temperature and high-pressure environment of downhole tools such as packers and bridge plugs in actual working conditions. According to API 11D1 standard, V0 level verification tests are carried out, including gas tests, axial load tests, temperature cycle tests, and zero gas bubble acceptance standards for performance testing of packers and bridge plugs. It includes envelope curve verification tests for downhole tools, as well as pressure and temperature resistance tests for other instruments and tools that require high-temperature and high-pressure environment testing. At the same time, it provides testing means for the development of new downhole tools.

Shenzhen Fluid Science&Technology Corp., Ltd.

Headquarter:

No. 513A, East Block, Coast Building, Nanshan District, Shenzhen, Guangdong, China

Tel:

© Shenzhen Fluid Science&Technology Corp., Ltd. ALL RIGHTS RESERVED | 粤ICP备10233873号 | Legal Declaration